Page 35 - HKK Product Catalogue 2025

P. 35

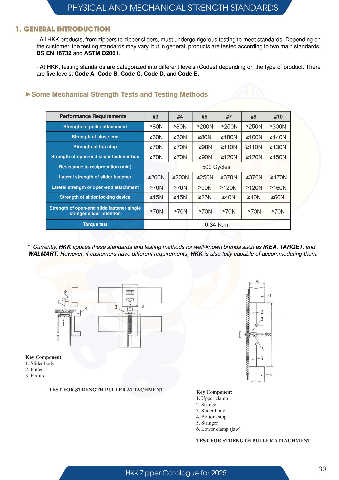

PHYSICAL AND MECHANICAL STRENGTH STANDARDS

1. GENERAL INTRODUCTION

- All HKK products, from zippers to zipper sliders, must undergo rigorous testing to meet standards. Depending on

the customer, the testing standards may vary, but in general, products are tested according to two main standards:

BS EN 16732 and ASTM D2061.

- At HKK, testing standards are categorized into different levels (Codes) depending on the type of product. There

are five levels: Code A, Code B, Code C, Code D, and Code E.

►Some Mechanical Strength Tests and Testing Methods

Performance Requirements #3 #4 #5 #7 #8 #10

Strength of puller attachment ≥80N ≥80N ≥200N ≥250N ≥250N ≥300N

Strength of close-end ≥60N ≥60N ≥80N ≥100N ≥100N ≥140N

Strength of top stop ≥70N ≥70N ≥90N ≥110N ≥110N ≥130N

Strength of open-end slider fastener box ≥70N ≥70N ≥90N ≥120N ≥120N ≥150N

Resistance to reciprocation (min) 500 Cycles

Lateral strength of slider fastener ≥200N ≥200N ≥250N ≥370N ≥370N ≥470N

Lateral strength of open-end attachment ≥70N ≥70N ≥90N ≥120N ≥120N ≥160N

Strength of slider locking device ≥15N ≥15N ≥25N ≥40N ≥40N ≥60N

Strength of open-end slide fastener single

stringer slider retention ≥70N ≥70N ≥70N ≥70N ≥70N ≥70N

Torque test 0.34 N.m

* Currently, HKK applies these standards and testing methods for well-known brands such as IKEA, TARGET, and

WALMART. However, if customers have different requirements, HKK is also fully capable of accommodating them.

Key Component

1. Slider body

2. Puller

3. Fixture

TEST FOR STRENGTH PULLER ATTACHMENT

Key Component

1. Upper clamp

2. Stringer

3. Slider body

4. Bottom stop

5. Stringer

6. Lower clamp (jaw)

TEST FOR STRENGTH PULLER ATTACHMENT

HKK Zipper Catalogue for 2025 30

HKK Zipper Catalogue for 2025